RemovAL

June 28, 2023

We are thrilled to announce the successful completion of the Removal project, culminating in a highly productive final meeting held in the beautiful city of Athens on June 26th and 27th. This gathering marked a significant milestone in our journey, providing a platform to showcase the remarkable results achieved by our consortium. During the final meeting, we had the privilege of presenting the incredible outcomes of our collaborative efforts. The achievements were nothing short of remarkable, underscoring the transformative impact of our collective work. It was a truly magnificent experience to share these accomplishments with the project officers and fellow […]

May 24, 2023

Update RequiredTo play the media you will need to either update your browser to a recent version or update your Flash plugin

Demonstrated at a prototype microwave furnace the production of metallic iron from processing bauxite residue with other industrial by-products

May 24, 2023

Update RequiredTo play the media you will need to either update your browser to a recent version or update your Flash plugin

Demonstrated at pilot scale the production of lightweight aggregates and high performance binders, through different thermal treatments of bauxite residue

May 24, 2023

Update RequiredTo play the media you will need to either update your browser to a recent version or update your Flash plugin

The industrial extraction of aluminium oxide from bauxite ore, leads also to the production of the Bauxite Residue by-product, which contains the remaining minerals of the bauxite ore. Under the RemovAl H2020 project, Acciona and Aughinish Alumina refinery have demonstrated a technology to recover Bauxite Residue and other industrial residues such as Ground Granulated Blast Furnace Slag (residue from iron production) and Pulverised Fly Ash (residue from coal combustion) to produce high performance road sublayer. This technology was engineered to re-use large quantity of bauxite residue, which is widely available in all countries where alumina is produced, to get to […]

May 24, 2023

Update RequiredTo play the media you will need to either update your browser to a recent version or update your Flash plugin

As part of the RemovAL H2020 project, Aughinish has demonstrated a technology to reduce the total soda in Bauxite Residue (BR) to less than 0.5% on a Na2O basis. The technology required the reaction of the BR with calcium hydroxide under specific conditions and time to produce the very low soda material, also termed Dealkalised BR. To-date, samples of the treated residue have been shipped to 12 different companies and research institutions to investigate its use as a supplementary cementitious material (SCM), as well as in the production of geopolymers, dense monoliths and slip-bricks. The pilot plant has demonstrated that […]

January 27, 2023

The industrial extraction of aluminium oxide from bauxite ore, leads also to the production of the Bauxite Residue by-product, which contains the remaining minerals of the bauxite ore. Under the RemovAl H2020 project, #MYTILINEOS has demonstrated a technology to recover metallic iron and slag from the Bauxite Residue in an Electric Arc Furnace. The slag of the process, which is usually a metallurgical waste stream, has been chemically designed to be usable in numerous applications ranging from use as raw material for aluminium and scandium oxide extraction to clinker substitute for cement production. Thus, this tunable process allows for the […]

November 22, 2022

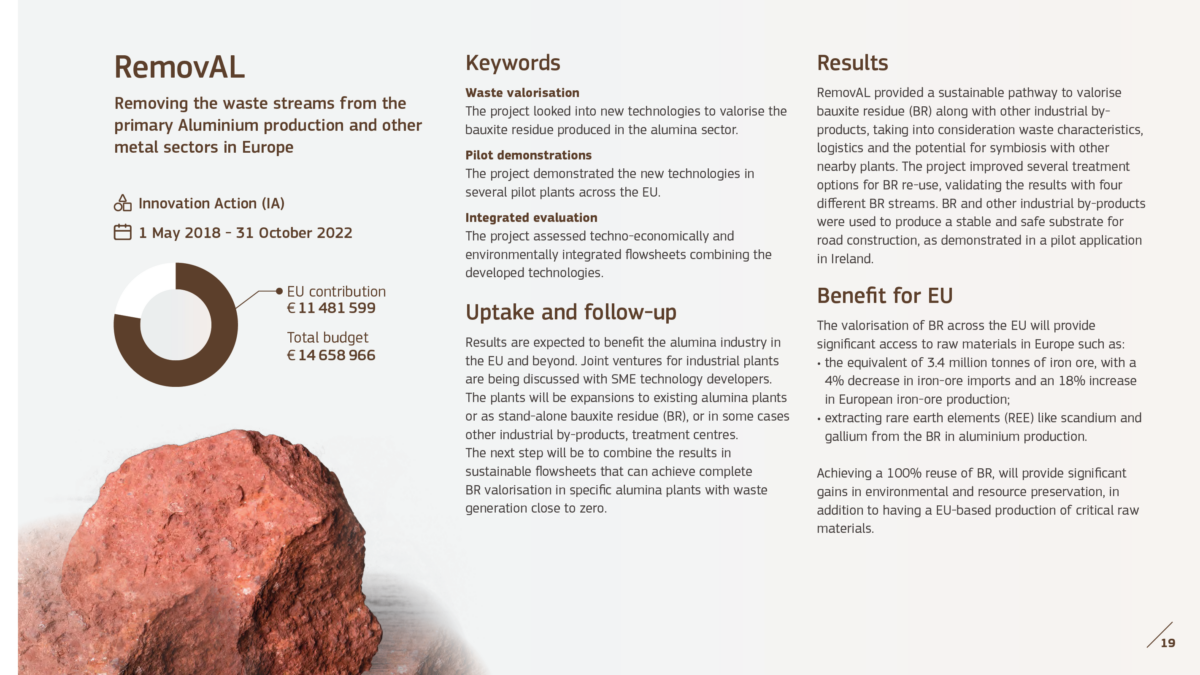

In the context of the EU Raw Materials Week, HaDEA organises the EU Horizon Technology Success Stories event,showcasing projects that are achieving, or have achieved, remarkable success in the relevant fields. The aim of this event goes beyond informing about the progress of the selected projects. The objective is to highlight how activities in the area of raw materials will benefit from project developments, or in broader terms how industry and society benefitfrom EU research funding. RemovAL took part in the event and is now featured in the resulting publication as a Technology Success Story. The publication identifies the following […]

November 7, 2022

“Turning residues of the aluminium industry into resources” European Aluminium organised the final stakeholders’ workshop for the EU-funded RemovAL project in Athens on 10 October. It was held as a hybrid event in collaboration with the ICSOBA 2022 conference and the 4th Bauxite Residue Valorisation and Best Practices Conference in order to maximise synergies between industry and academia. The workshop gathered around 100 experts, who had the opportunity to discuss the key learnings and achievements of RemovAL as well as best practices for turning bauxite residue into a valuable raw material for other industries. The workshop ended by a panel […]

October 25, 2022

On the 14th of October as part of the ICSOBA 2022 field trip, ICSOBA delegates and Removal partners visited the construction site of the RemovAl ‘Bauxite House’ at the Aspra Spitia residence area next to the MYTILINEOS alumina and aluminium plant. This information pavilion is constructed from Bauxite residue prototype building materials and will house an exhibition of technologies and items produced during the RemovAl project. In the photo you can see an external wall that has been covered with bauxite residue brick slips produced from Resourcefull, while Removal scientists are sitting on bench made from Bauxite Residue high strength binder […]