The groundbreaking objective in RemovAL is the first ever Pilot scale demonstration of a holistic Bauxite Residue valorization in a financially viable and ecologically sustainable manner.

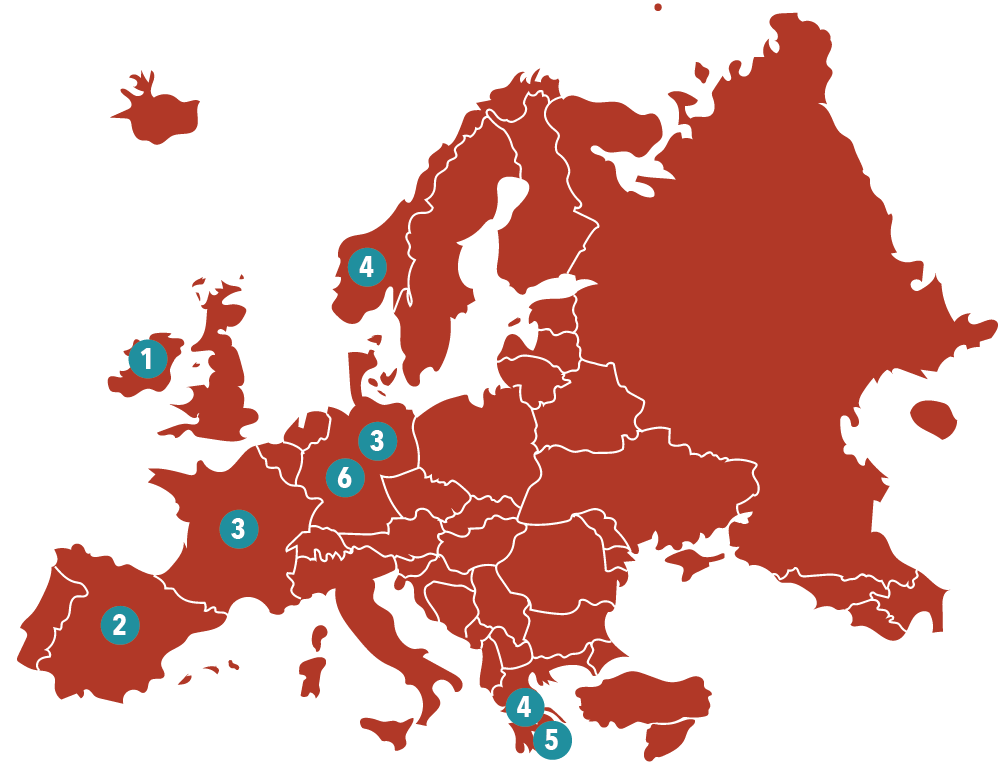

6 innovative pilot plants across Europe

Combined they will form a network of technological nodes, enabling optimum processing flow sheets 2 for valorising the produced bauxite residue

The validation will be done for 3 European alumina producers (representing 44% of the European alumina production) and one legacy site own

de-alkanization

Demonstrate at pilot scale the de-alkalization technology to remove alkali content from bauxite residue at levels below 0.5% wt, making it suitable for various applications

At least 40 t of bauxite residue will be processed by AAL at a mobile pilot plant in IRELAND

As part of the RemovAL H2020 project, Aughinish has demonstrated a technology to reduce the total soda in Bauxite Residue (BR) to less than 0.5% on a Na2O basis. The technology required the reaction of the BR with calcium hydroxide under specific conditions and time to produce the very low soda material, also termed Dealkalised BR. To-date, samples of the treated residue have been shipped to 12 different companies and research institutions to investigate its use as a supplementary cementitious material (SCM), as well as in the production of geopolymers, dense monoliths and slip-bricks. The pilot plant has demonstrated that in addition to producing a useable material, the caustic or soda bound in the BR can be recovered back into the Bayer Process greatly improving the economics of the treatment with calcium hydroxide

green soil stabilizer

Demonstrate the use of processed bauxite residue as green soil stabilizer for civil works applications, though the stabilization of bauxite residue with other industrial by products

At least 800 t of bauxite residue will be processed and used by ACCIONA as a raw material for the construction of a road in Spain

The industrial extraction of aluminium oxide from bauxite ore, leads also to the production of the Bauxite Residue by-product, which contains the remaining minerals of the bauxite ore. Under the RemovAl H2020 project, Acciona and Aughinish Alumina refinery have demonstrated a technology to recover Bauxite Residue and other industrial residues such as Ground Granulated Blast Furnace Slag (residue from iron production) and Pulverised Fly Ash (residue from coal combustion) to produce high performance road sublayer. This technology was engineered to re-use large quantity of bauxite residue, which is widely available in all countries where alumina is produced, to get to a zero-waste process that can produce added value products such as road sublayers and many other civil works applications.

lightweight aggregates &

high performance binders

Demonstrate at pilot scale the production of lightweight aggregates and high performance binders, through different thermal treatments of bauxite residue

At least 10 t of bauxite residue will be processed in the RIO TINTO Pilot plant in France

ferro-silicon alloy

Demonstrate at pilot scale the production of ferro-silicon alloy from Electric Arc Furnace (EAF) co-processing of bauxite residue with other industrial by-products, like Spent Pot Lining (SPL) form aluminium primary production

At least 50 t of Bauxite Residue will be processed in the AoG Pilot plant in Greece and in the ELKEM pilot plant in Norway

Under the RemovAl H2020 project, #MYTILINEOS has demonstrated a technology to recover metallic iron and slag from the Bauxite Residue in an Electric Arc Furnace. The slag of the process, which is usually a metallurgical waste stream, has been chemically designed to be usable in numerous applications ranging from use as raw material for aluminium and scandium oxide extraction to clinker substitute for cement production. Thus, this tuneable process allows for the reuse of the bauxite residue stream in a zero waste process that produces added value products and effectively allows the complete utilization of bauxite ore mined for aluminium production.

microwave furnace

Demonstrate at a prototype microwave furnace the production of metallic iron from processing bauxite residue with other industrial by-products

At least 250 kg of Bauxite Residue will be processed in CEINNMAT’s mobile prototype plant in both Spain and Greece

hydrometallurgy

Demonstrate the production of REE concentrate, Ga concentrate, alumina/soda solution and rutile concentrate from the hydrometallurgical processing of engineered slags/sinters produced in RemovAL pyrometallurgical pilot plants. Ga is co-extracted both from the slag and the Bayer liquor

At least 500 kg of slag and 100 lt of Bayer liquor will be processed at RWTH/MEAB pilot plant in Germany